[gtranslate]

- Company

- Solutions

- SanitationEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

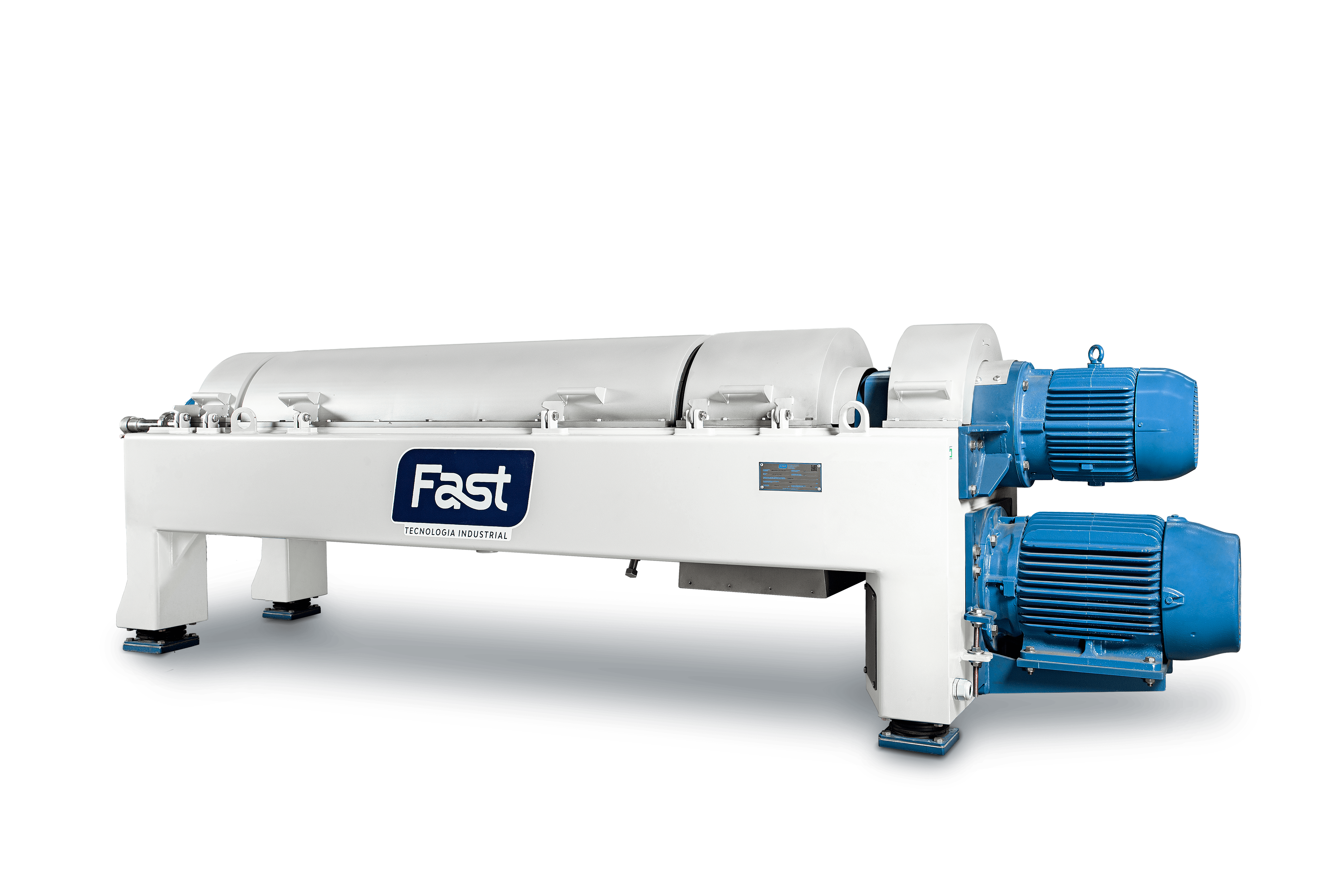

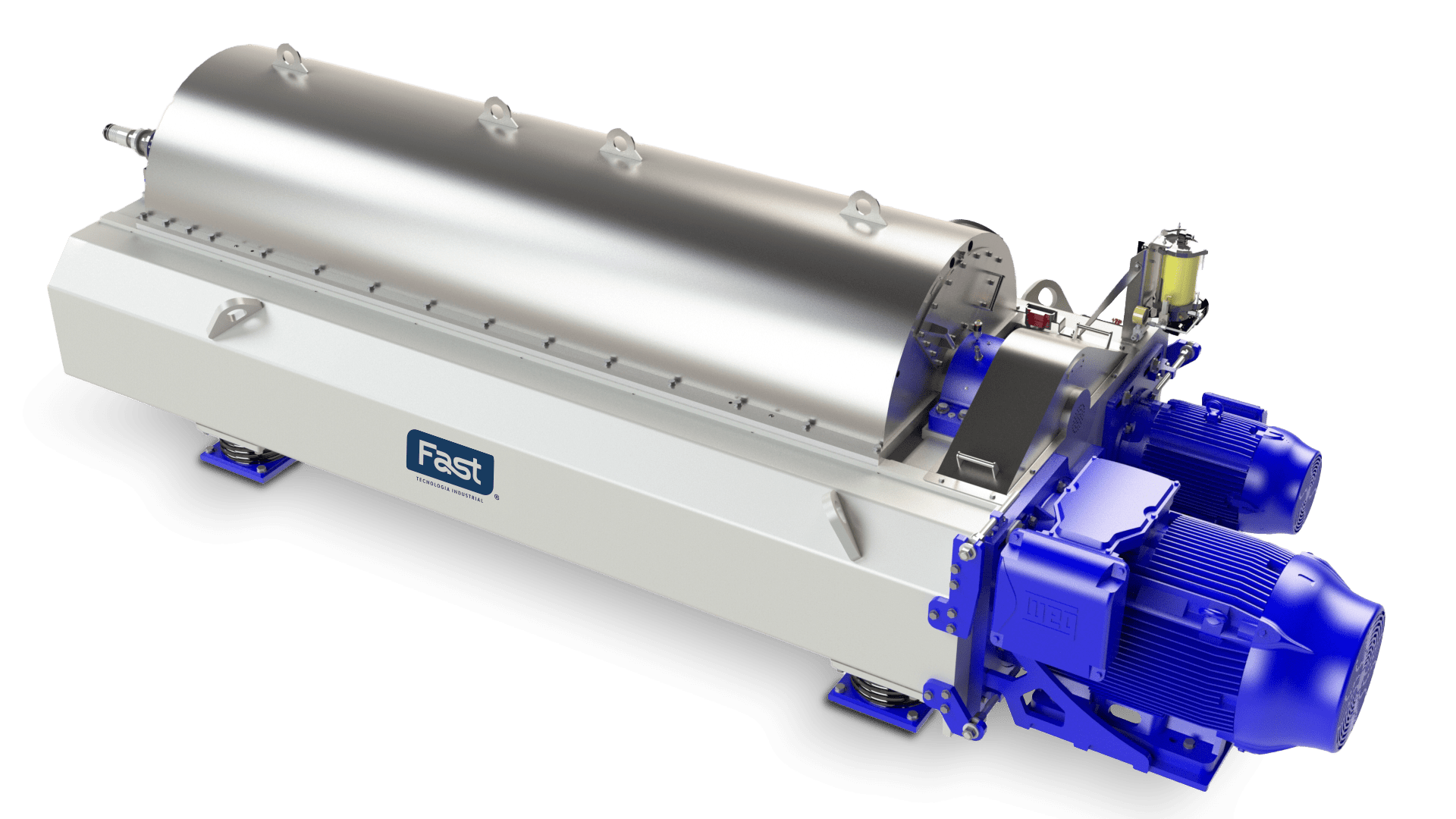

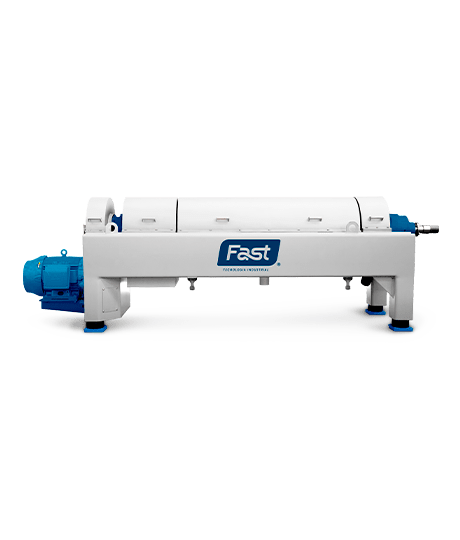

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

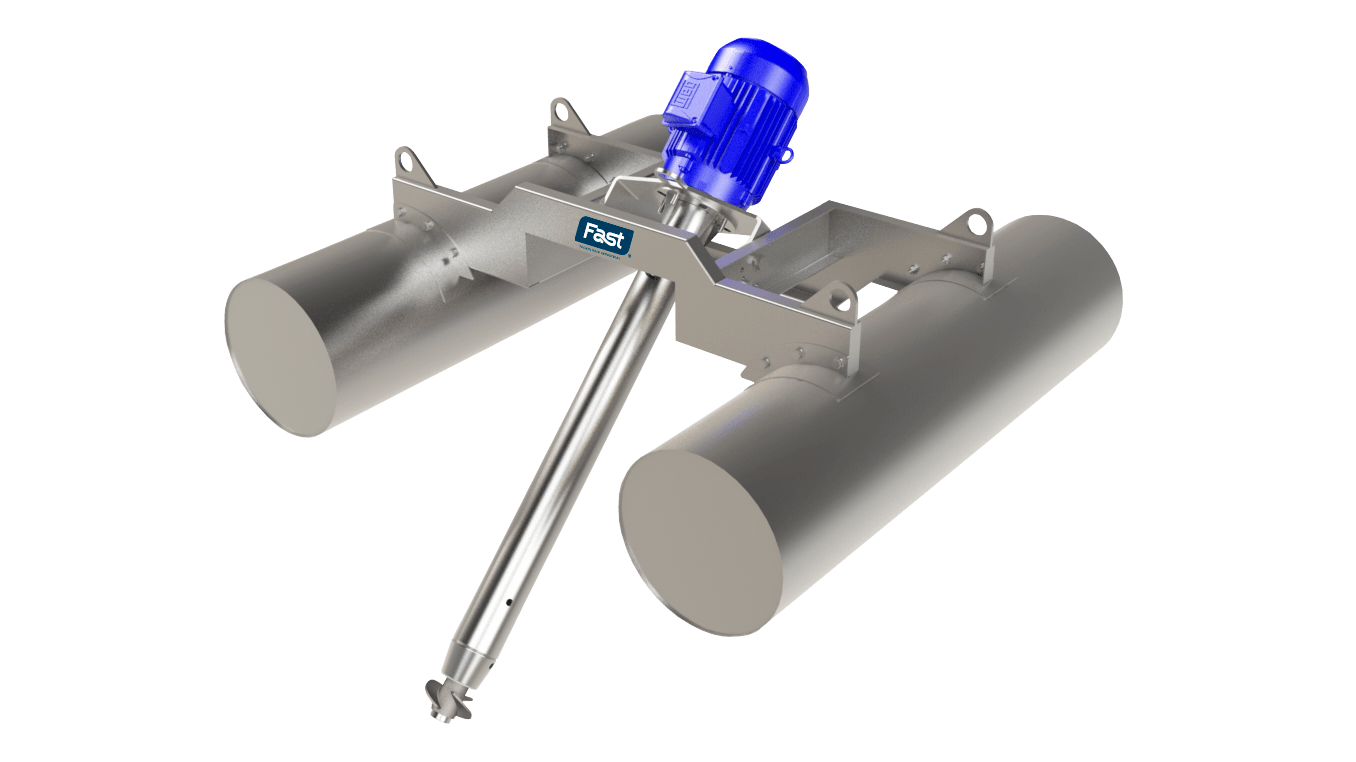

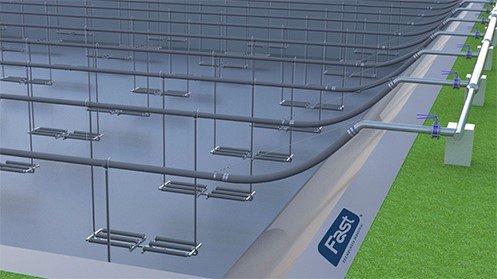

- Hyperbolic Agitator

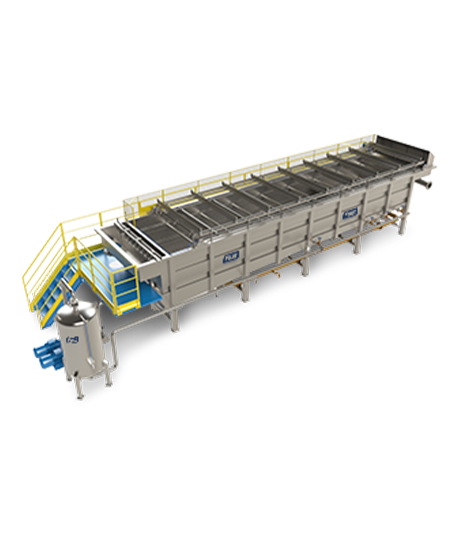

- Water Treatment Plant - ETA

- Compact Flotation Unit

- Polypropylene Tanks

- Modular Tanks

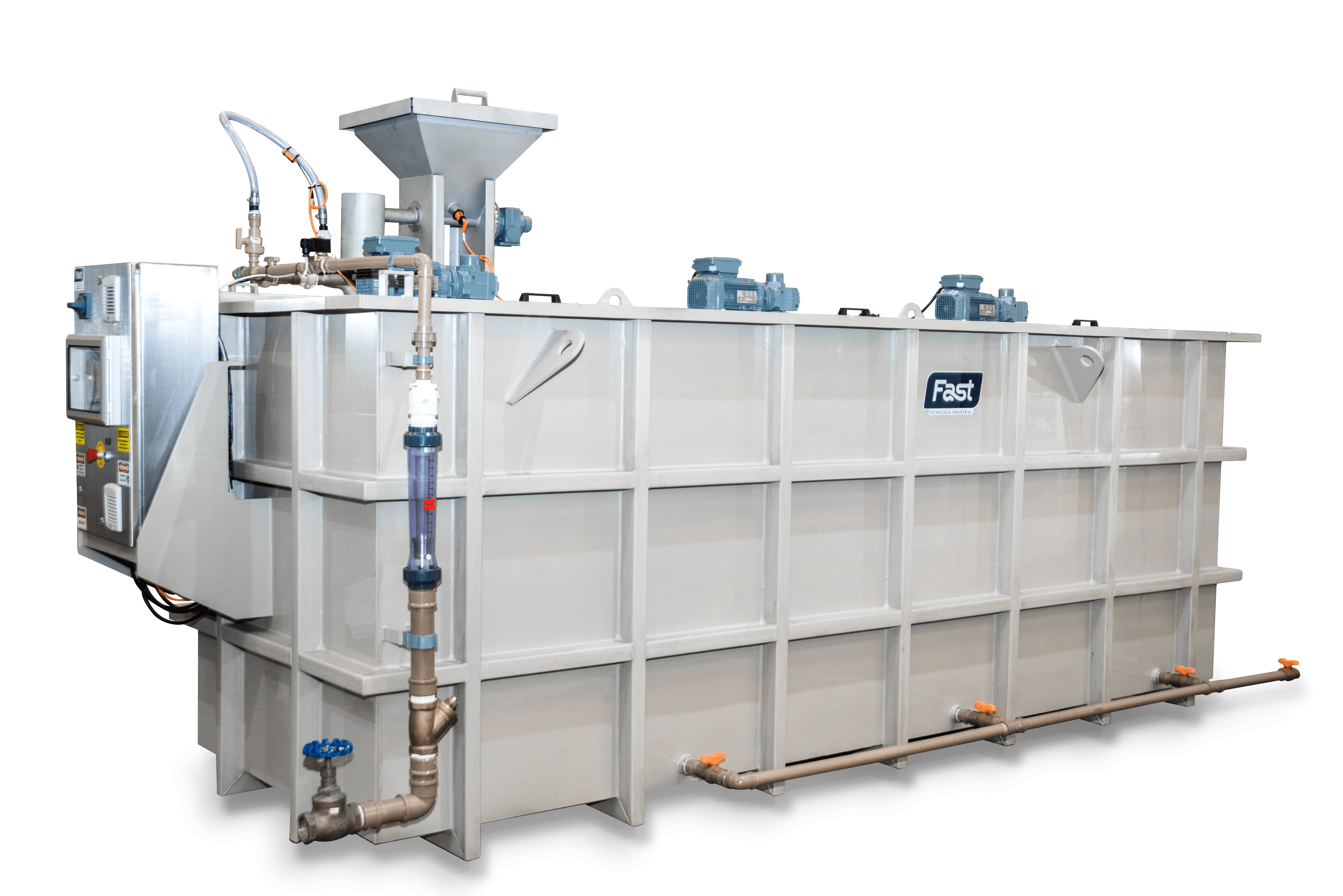

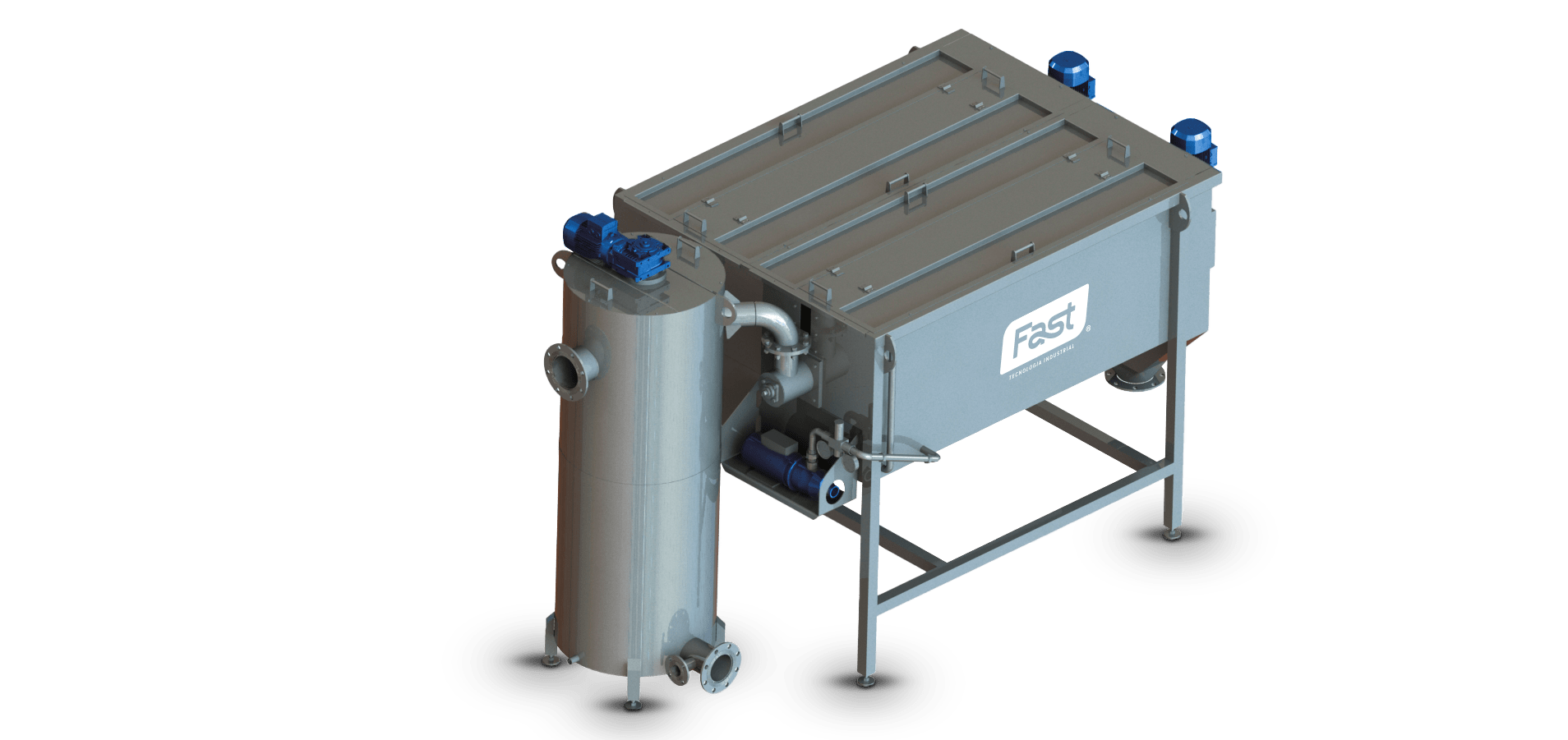

- Polymer Preparation System

- Scraper Bridge

- Automation and Electrical Panel

- Dortmund Decanter

- Surface Aerator

- Sludge thickener

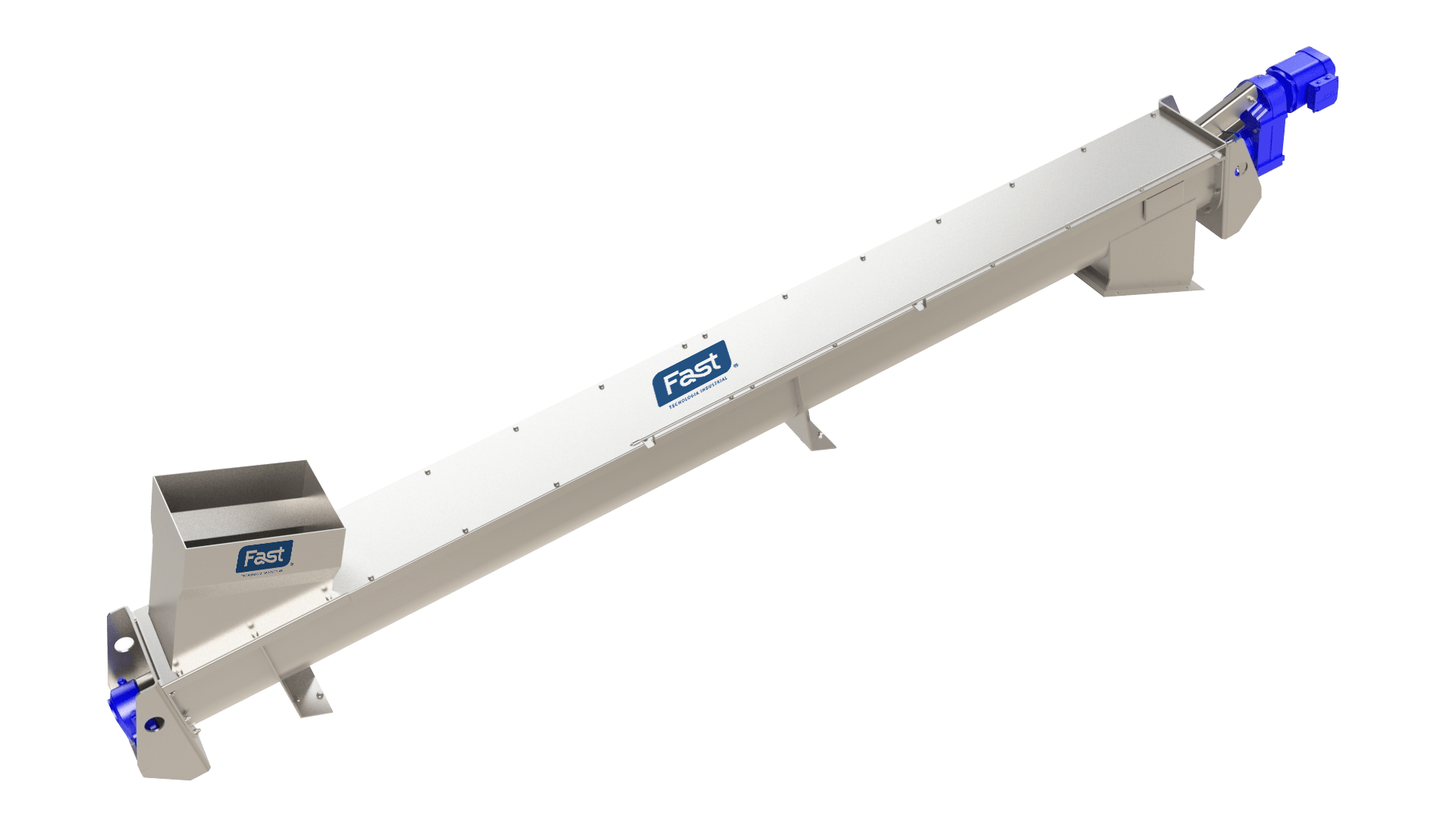

- Screw Conveyor

- Static Sieve

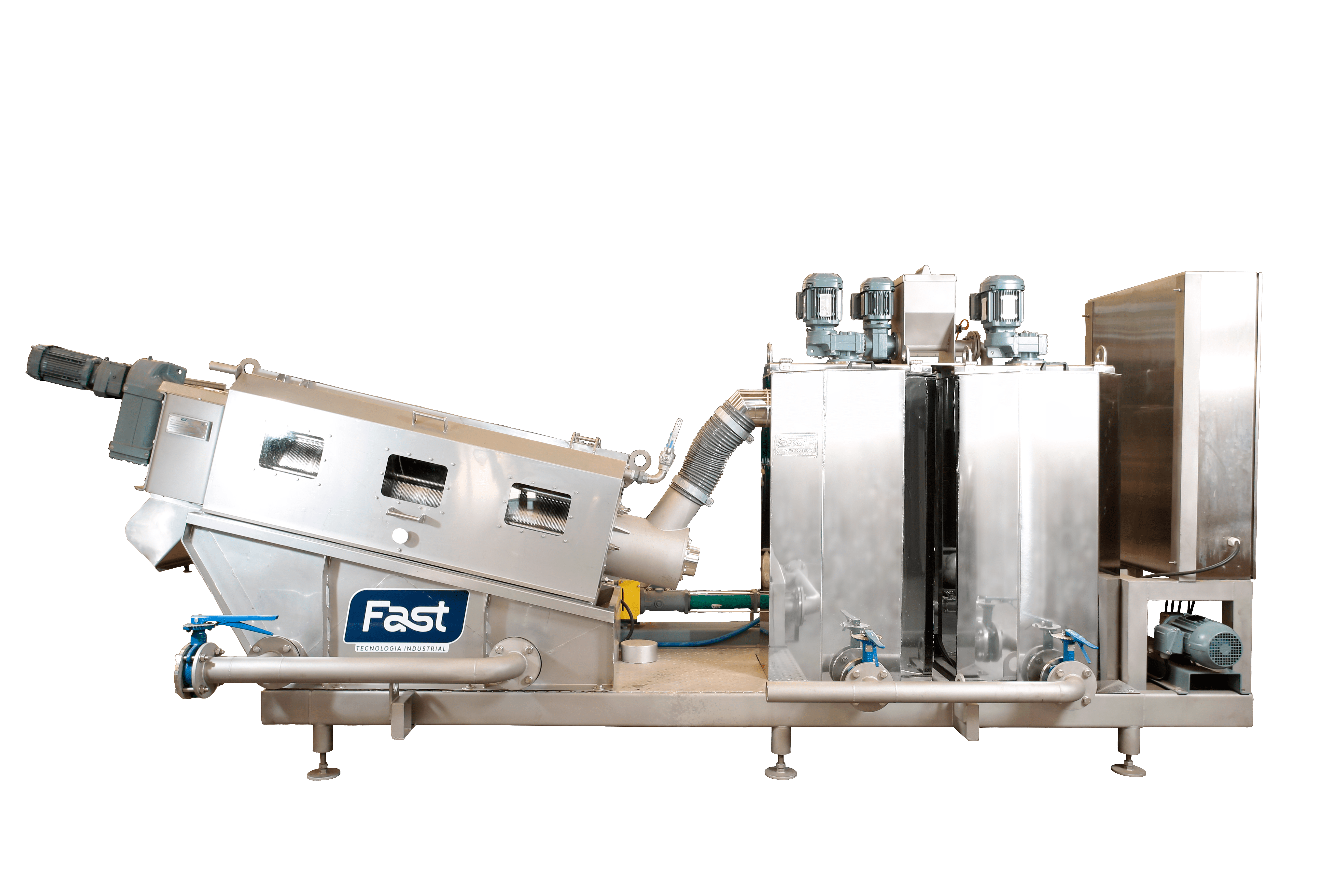

- Screw Press

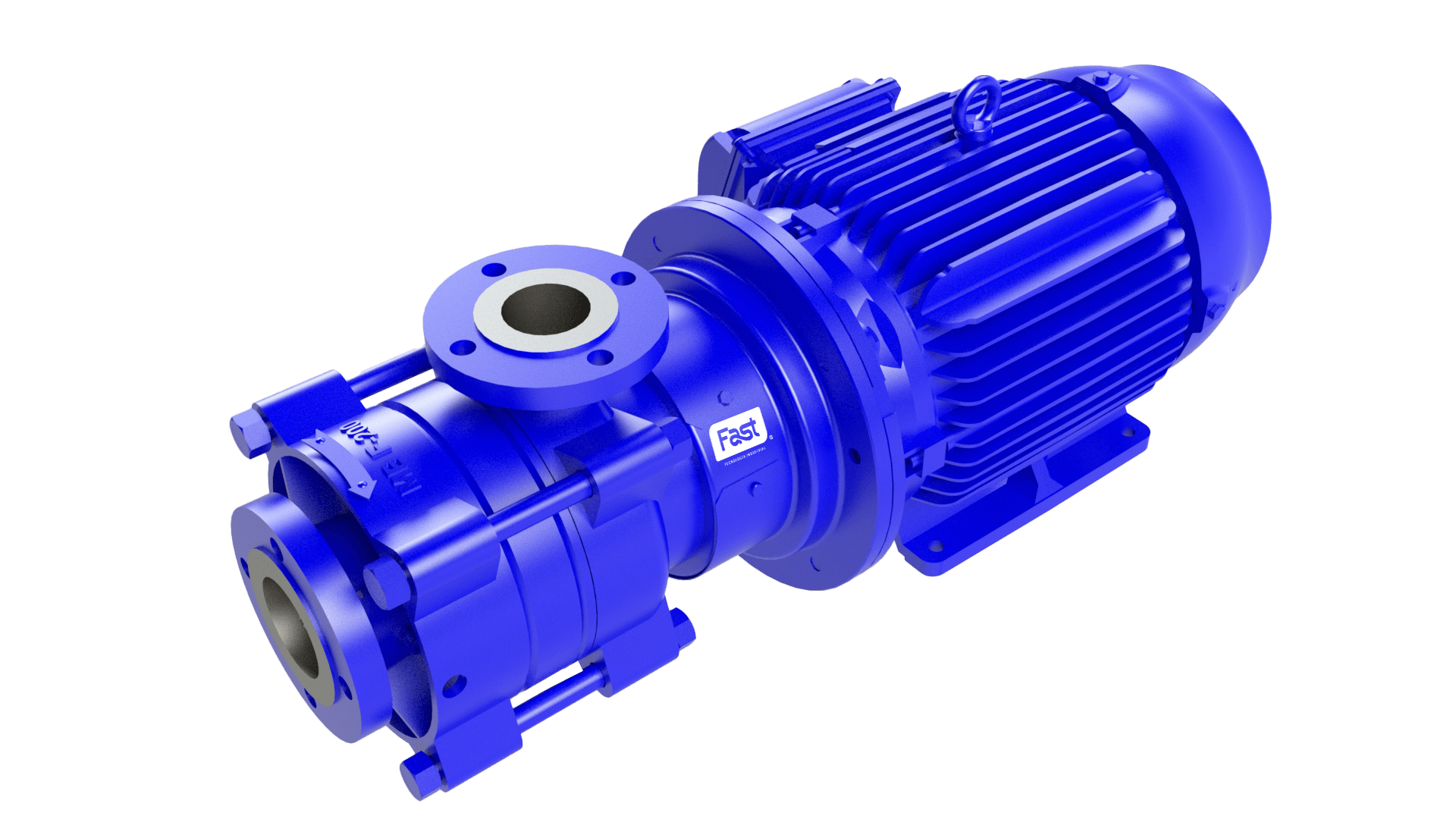

- Microbubble Pump

- Rotary Sieve

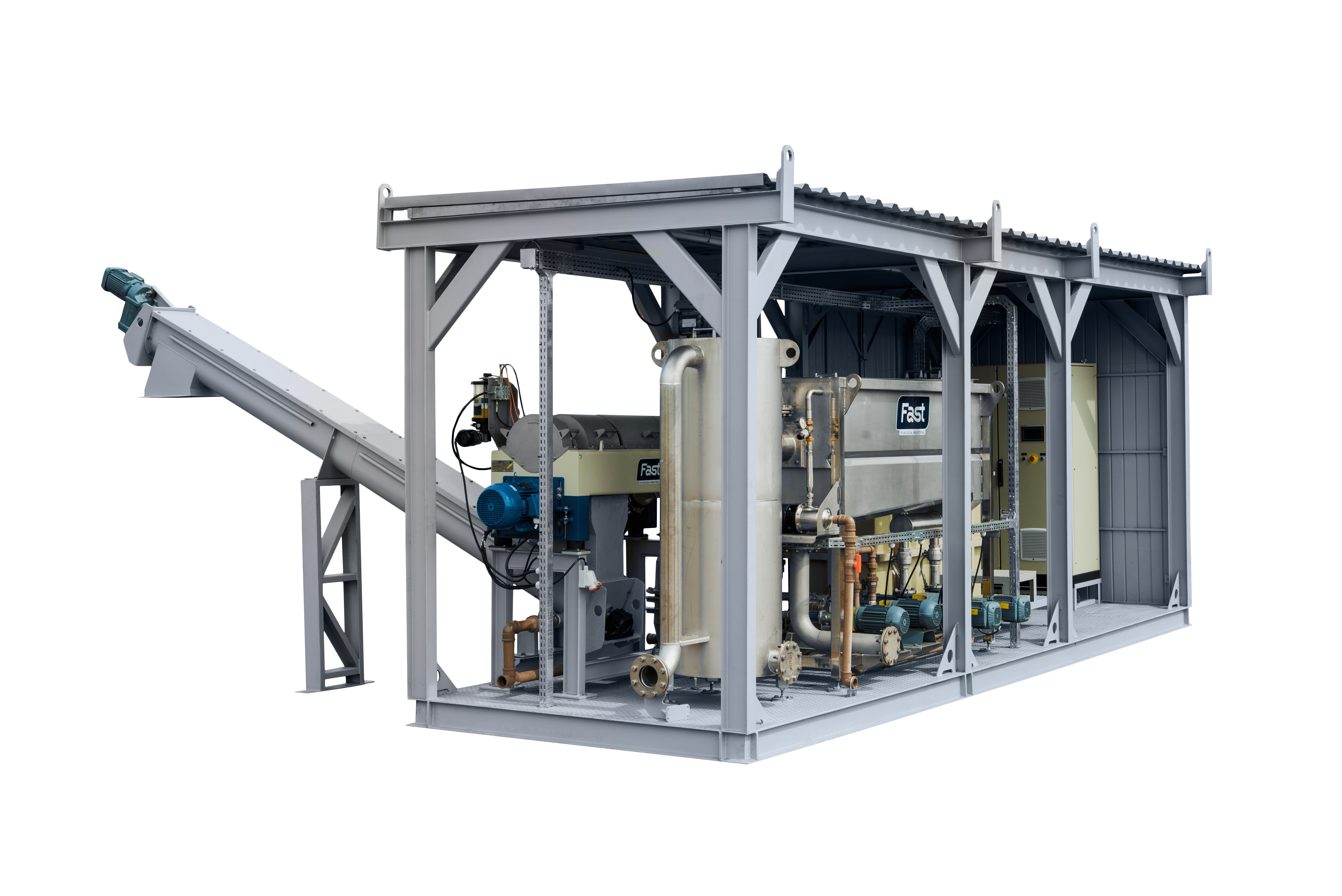

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

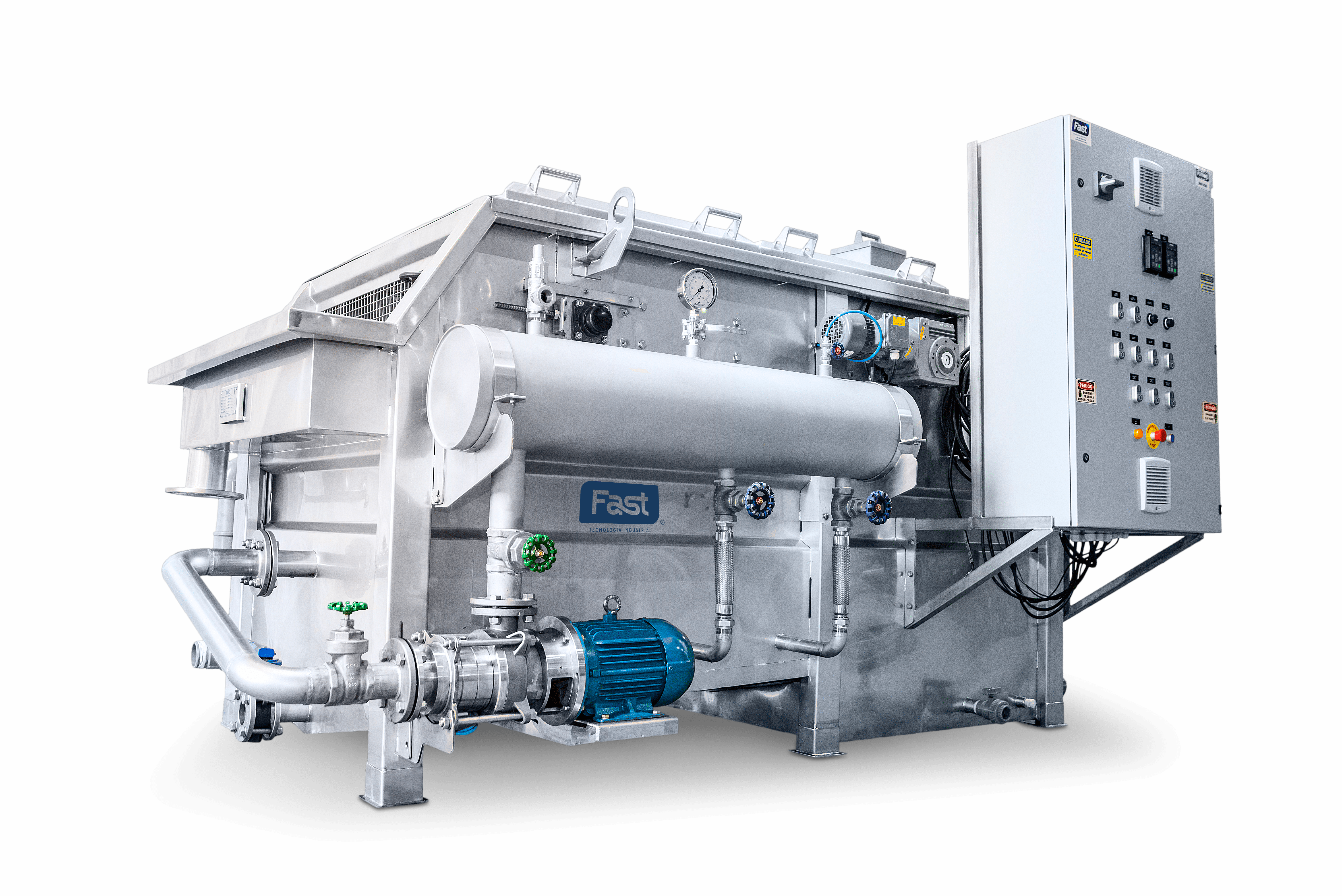

- Dissolved air floatation machine

- SlaughterhousesEquipaments

- Hydrolyzer

- Disc Dryer

- Gas Condenser

- Fast Drive Cetrifugal Tridecanter

- Flour Mill | MFF

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Fast Continuous Press | PCF

- Hyperbolic Agitator

- Fast Batch Digester | DBF

- Fast Continuous Digester | DCF

- Water Treatment Plant - ETA

- Fast Shredder | TRF

- Fast Lamella Pump | BLF

- Compact Flotation Unit

- Polypropylene Tanks

- Modular Tanks

- Polymer Preparation System

- Scraper Bridge

- Automation and Electrical Panel

- Surface Aerator

- Sludge thickener

- Static Sieve

- Screw Press

- Microbubble Pump

- Rotary Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Vertical Centrifuge

- Dissolved air floatation machine

- Palm OilEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Water Treatment Plant - ETA

- Oil Tank, Buffer Tank and Homogenization Tank

- Empty Bunch Dosing Screw

- desanding machine

- Centrifugal Pump

- Fruit Digester

- Automation and Electrical Panel

- Fruit Press

- Empty Bunch Chopper

- Empty Curl Press

- Effluent Treatment Plant (ETE)

- Dissolved air floatation machine

- Olive OilEquipaments

- Fast Drive EAF Centrifugal Decanter

- Olive Oil Tank

- EAF Centrifugal Decanter

- Mixer

- Olive Oil Filter

- Stone Separator

- Automation and Electrical Panel

- Fast 100 Monobloc Extractor

- EAF Vertical Centrifuge

- Leaf Eliminator

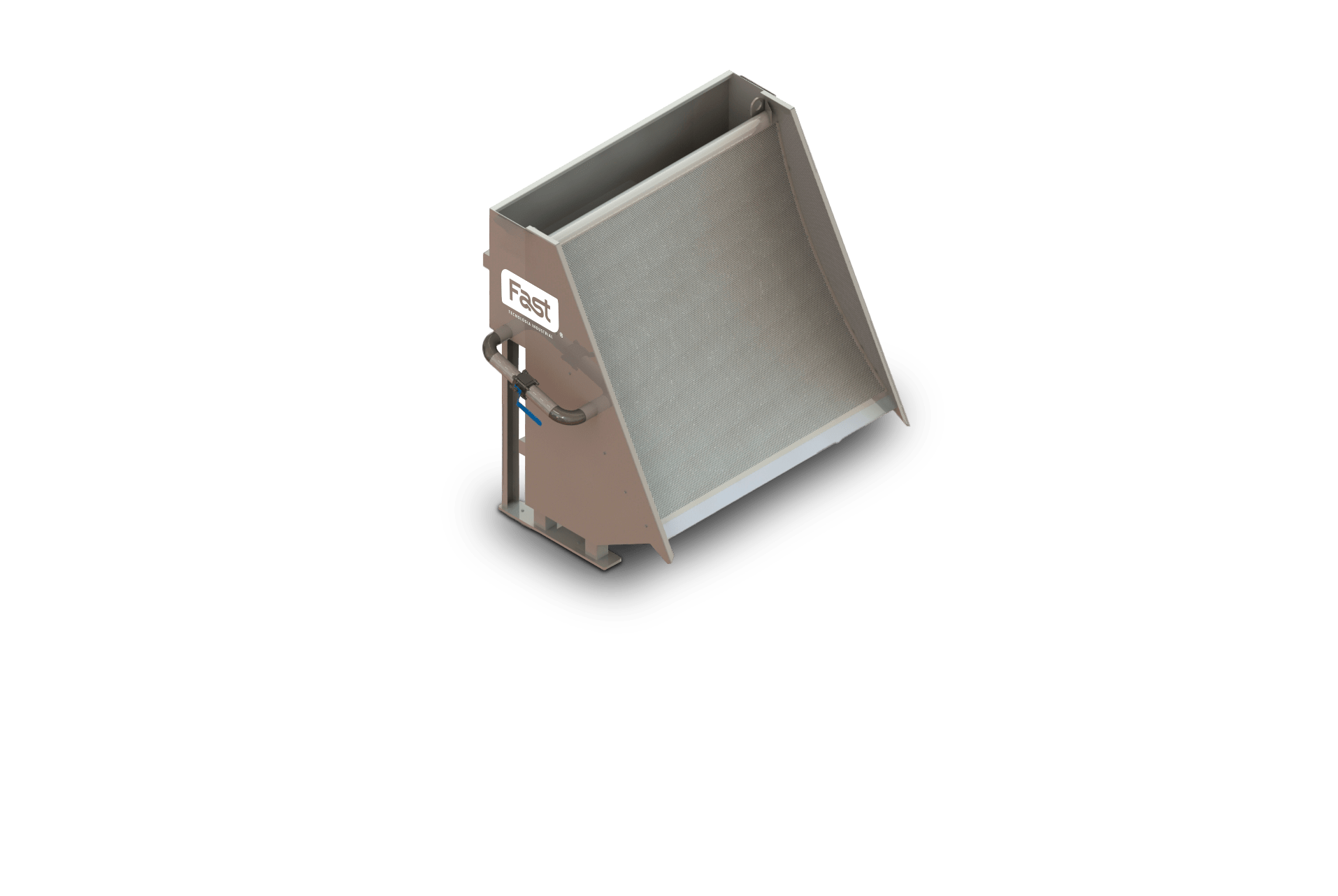

- Reception Hopper

- MiningEquipaments

- Fast Drive Cetrifugal Tridecanter

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Thickener

- Water Treatment Plant - ETA

- Polypropylene Tanks

- Automation and Electrical Panel

- Sludge thickener

- Screw Conveyor

- Static Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Dissolved air floatation machine

- Paper and PulpEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Hyperbolic Agitator

- Water Treatment Plant - ETA

- Polypropylene Tanks

- Polymer Preparation System

- Scraper Bridge

- Automation and Electrical Panel

- Surface Aerator

- Sludge thickener

- Screw Conveyor

- Static Sieve

- Screw Press

- Microbubble Pump

- Rotary Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Dissolved air floatation machine

- Fast RenderingEquipaments

- Hydrolyzer

- Disc Dryer

- Gas Condenser

- Flour Mill | MFF

- Tridecanter Centrifugal

- Decanter Centrifugal

- Fast Continuous Press | PCF

- Fast Batch Digester | DBF

- Fast Continuous Digester | DCF

- Fast Shredder | TRF

- Fast Lamella Pump | BLF

- Fast GrainEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Disc Dryer

- Water Treatment Plant - ETA

- Polypropylene Tanks

- Automation and Electrical Panel

- Static Sieve

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Vertical Centrifuge

- Dissolved air floatation machine

- DairyEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Hyperbolic Agitator

- Water Treatment Plant - ETA

- Compact Flotation Unit

- Polypropylene Tanks

- Polymer Preparation System

- Automation and Electrical Panel

- Sludge thickener

- Static Sieve

- Screw Press

- Microbubble Pump

- Rotary Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Vertical Centrifuge

- Dissolved air floatation machine

- BeveragesEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Hyperbolic Agitator

- Water Treatment Plant - ETA

- Compact Flotation Unit

- Polypropylene Tanks

- Polymer Preparation System

- Scraper Bridge

- Automation and Electrical Panel

- Sludge thickener

- Static Sieve

- Screw Press

- Microbubble Pump

- Rotary Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Vertical Centrifuge

- Dissolved air floatation machine

- AçaíEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Water Treatment Plant - ETA

- Automation and Electrical Panel

- Sludge thickener

- Static Sieve

- Screw Press

- Effluent Treatment Plant (ETE)

- Dissolved air floatation machine

- Avocado OilEquipaments

- Fast Drive EAF Centrifugal Decanter

- EAF Centrifugal Decanter

- Mixer

- Automation and Electrical Panel

- EAF Vertical Centrifuge

- Leaf Eliminator

- Reception Hopper

- Other ApplicationsEquipaments

- Fast Drive Cetrifugal Tridecanter

- Tridecanter Centrifugal

- Fast Drive Centrifugal Decanter

- Decanter Centrifugal

- Hyperbolic Agitator

- Water Treatment Plant - ETA

- Compact Flotation Unit

- Polypropylene Tanks

- Modular Tanks

- Polymer Preparation System

- Scraper Bridge

- Automation and Electrical Panel

- Dortmund Decanter

- Surface Aerator

- Sludge thickener

- Screw Conveyor

- Static Sieve

- Screw Press

- Microbubble Pump

- Rotary Sieve

- Mobile Skid Treatment Unit

- Effluent Treatment Plant (ETE)

- Pressurized WTP

- Vertical Centrifuge

- Dissolved air floatation machine

Segments and applicationsTechnological solutions for phase separation in the most diverse applicationsAll products

Oferecemos soluções completas em separação, desenvolvidas para maximizar a performance dos seus processos industriais. Seja qual for o desafio — separação sólido-líquido, clarificação ou concentração — temos o equipamento ideal para entregar eficiência, economia e confiabilidade

- Sanitation

- Estimates

- Cases

- Customers

- Blog

- Contact

- Careers

[gtranslate]

[gtranslate]